pollen persimmon maqui saffron vacuum freeze dryer lyophilizer machine

- Packaging:

- Wooden case(fumigation free)

- Supply Ability:

- 20 Set/Sets per Quarter

- Port:

- SHANGHAI OR OTHER

Product Description

Model | FD-1C | FD-5C | FD-10C | FD-20C | FD-30C | FD-50C |

Control method | PLC touch screen | |||||

Working methods | quick freezing, lyophilization | |||||

Material | SUS304 | |||||

Drying area (m2) | 1 | 5 | 10 | 20 | 30 | 50 |

Loading capacity(kg) | 10 | 50 | 100 | 200 | 300 | 500 |

Tray size (mm) | 400*500*25 | 600*1000*25 | 800*1000*25 | 600*1000*25 | 800*500*20 | 600*1000*20 |

Tray pcs | 5 | 9 | 13 | 34 | 76 | 80 |

Tray form | SUS304, perforated or solid tray | |||||

Shelf | 8 | 13 | 18 | 38 | 40 | 86 |

Shelf temperature(°C) | -55~120 | |||||

Shelf medium | low temperature silicone oil | |||||

Vacuum pump | rotary vane pump | two-level pump | combined pump | |||

Working vacuum(pa) | <=130 | |||||

Ultimate vacuum(pa) | <10 | |||||

Defrosting method | hot water spray | hot water soaking | ||||

Compressor | copeland | |||||

Power | custom | |||||

Working environment temperature(°C) | <=40 | |||||

Rated power(kW) | 6 | 16 | 28 | 56 | 70 | 110 |

Size (mm) | 2000*700*1700 | 3000*1500*1800 | 3200*1600*2100 | 5000*2200*2500 | 6000*2600*2900 | 9000*3800*3500 |

Applying the principle of sublimation for drying. Rapid freezing of the material is achieved in low temperature, and then in a suitable vacuum environment the frozen water molecules will be directly sublimated into water vapor and then escape. The product obtained by drying is called lyophilisate and this process is called lyophilisation.

The material is always in the low temperature (frozen state) before drying, and the ice crystals are evenly distributed in the material. The sublimation process will not be concentrated due to dehydration, thus avoiding side effects such as foam and oxidation caused by water vapor. Dry matter was dry sponge porous, the volume is basically the same, very easy to dissolve in water and restitution. To the greatest extent to prevent physical and chemical and biological aspects of denaturation.

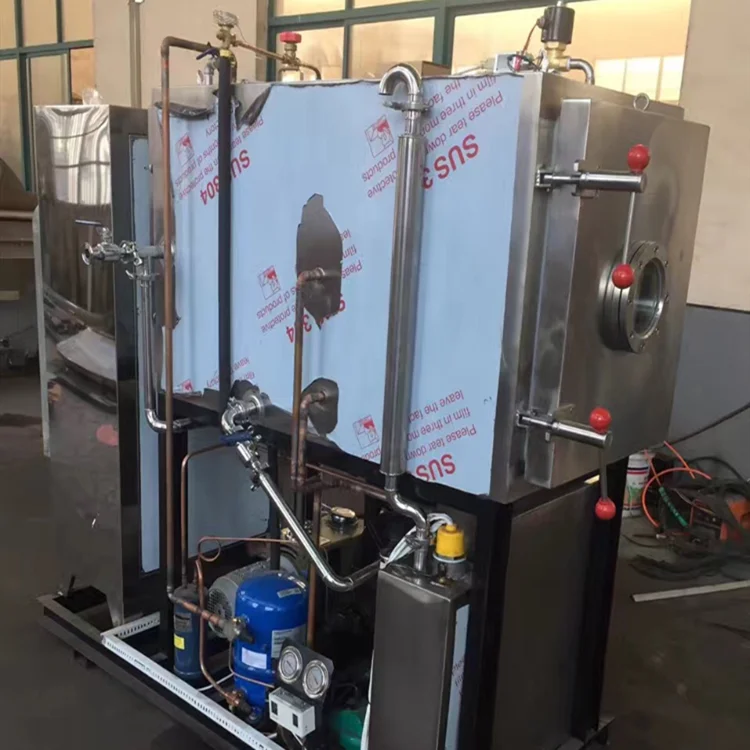

The material is always in the low temperature (frozen state) before drying, and the ice crystals are evenly distributed in the material. The sublimation process will not be concentrated due to dehydration, thus avoiding side effects such as foam and oxidation caused by water vapor. Dry matter was dry sponge porous, the volume is basically the same, very easy to dissolve in water and restitution. To the greatest extent to prevent physical and chemical and biological aspects of denaturation. The freeze dryer is composed of a refrigeration system, a vacuum system, a heating system and an electrical instrumentation control system. The main components is oven, condenser, refrigeration units, vacuum pumps, heating / cooling devices. Its working principle is to make the material be frozen below a certain temperature, and then under the conditions of the vacuum the solid state of the water (ice) is directly sublimated into water vapor and discharged out to get dry items.

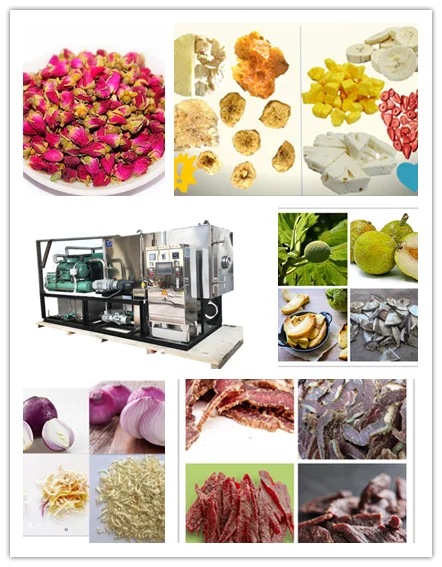

Application

ApplicationVacuum freeze-drying technology is widely applied in biological engineering, pharmaceutical industry, food industry, materials science and deep processing of agricultural and sideline products.

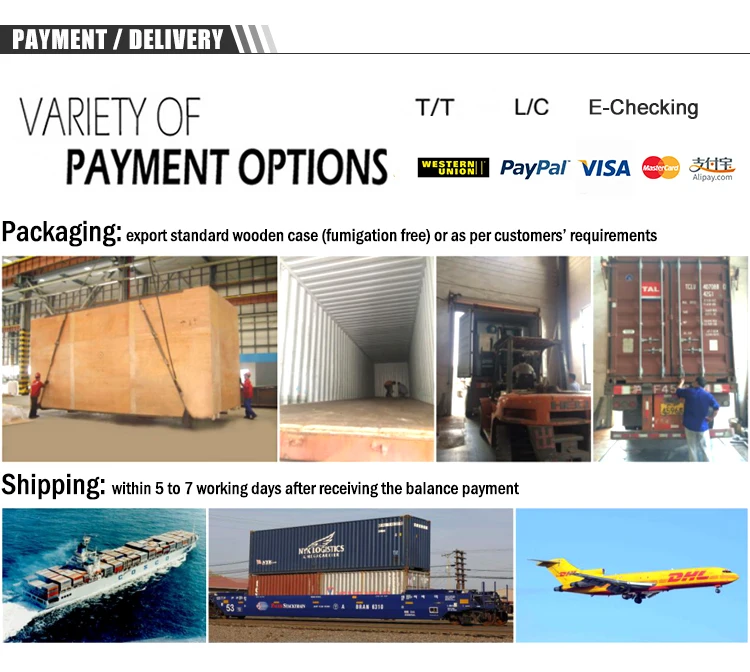

Packaging & ShippingPackaging: wooden case (fumigation free) or as per customers' requirementsShipping: within 5 to 7 working days after receiving the balance payment

Packaging & ShippingPackaging: wooden case (fumigation free) or as per customers' requirementsShipping: within 5 to 7 working days after receiving the balance payment  Our Services

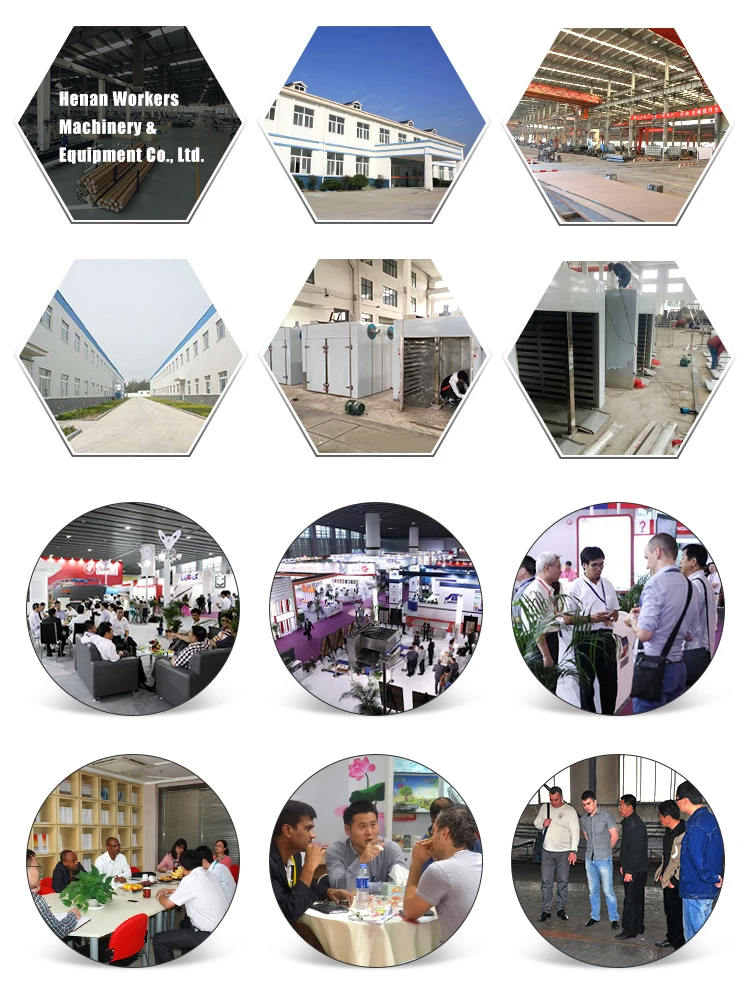

Our Services Company InformationHenan Workers Machinery Co., Ltd, established for over ten years, gained extensive experience in design and production of various drying machines applied in different industries and food processing equipment (both complete processing lines and individual machines) and packaging machines tailored to your precise needs.

Company InformationHenan Workers Machinery Co., Ltd, established for over ten years, gained extensive experience in design and production of various drying machines applied in different industries and food processing equipment (both complete processing lines and individual machines) and packaging machines tailored to your precise needs. With worldwide sales on five continents, WKS brand is among the world’s leading providers of drying machines and food processing equipment technology.

With her innovative engineers, well trained technicians, wide knowledge and long- standing experience, WKS serves its customers in each phase of the production.

WKS not only designs and manufactures each machine, but also assembles, operates, trains and carries technical responsibilities of every delivered equipment.

To ensure hygiene, durability and ease of maintenance, WKS uses the most advanced technology and materials. Whether you require a simple conveyor or high-tech automated equipment, WKS can supply the most suitable machine for your application. Instant supply of in-stock spare parts ensures your machinery serviced in the shortest time possible.

FAQQ1: Who is Henan Workers Machinery Co,. Ltd?

FAQQ1: Who is Henan Workers Machinery Co,. Ltd?A: Henan Workers Machinery Co,. Ltd is a manufacturing and trade enterprise engaged in drying, food processing and packaging industries with over ten years’ experience.Q2: What are your main products?

A: Our main products are Industrial Drying Machine (Hot air circulation drying machine/Microwave drying machine/Vacuum drying machine/spray drying machine/vibrating fluid bed drying machine, etc.), Food Processing Machine (cleaning/washing, pitting, peeling, slicing and grinding machine, etc.) and Packaging machine.Q3: What certificates do you have for your products?

A: All products are manufactured strictly complying with ISO9001: 2015, main certificates are CE, FCC, GOST, etc.Q4: What is the warranty of your products?

A: 1 year. All spare parts are free during this period, but you have to bear the airfare.Q5: Can you introduce your company's after - sales service team?

A: 24-hour hot-line service, complete components & parts are ready for supply anytime.

The company has a full-time after-sales service team , they are from the manufacturing staff who understands the operation of the equipment very well, they will solve all problems encountered by customers, and provide you with timely maintenance and use recommendations.Q6: What is the delivery time?

A: Normally 5 to 7 working days after receiving the balance payment.Q7: What is the terms of payment?

A: T/T, PayPal, West Union, E-checking, Credit Card, etc. Contact us if you need more details on Pharmaceutical Vacuum Drying Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Fruit Food Freeze Dehydrating Equipment、Vegetable Lyophilization Dehydrator. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Lyophilizer & Vacuum freeze dryer